Additional engineering highlights from previous EA 211 engines

● As with other engines in the EA 211 series, including earlier EVO versions, the 1.5 TSI evo2 benefits from several proven engineering solutions. One noteworthy feature is the lightweight drilled crankshaft with only four counterweights, which has a positive effect on reducing rotational inertia of the crank mechanism

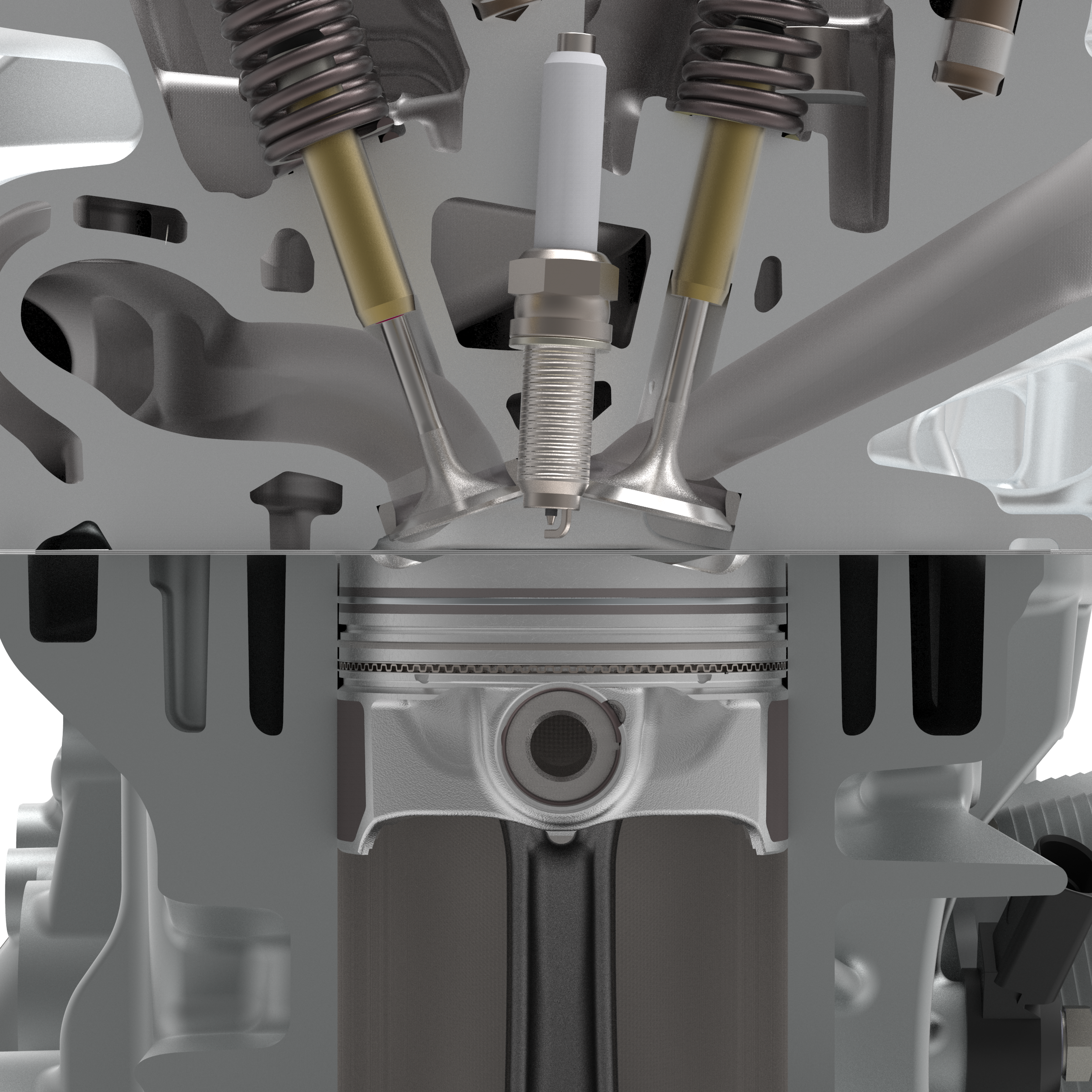

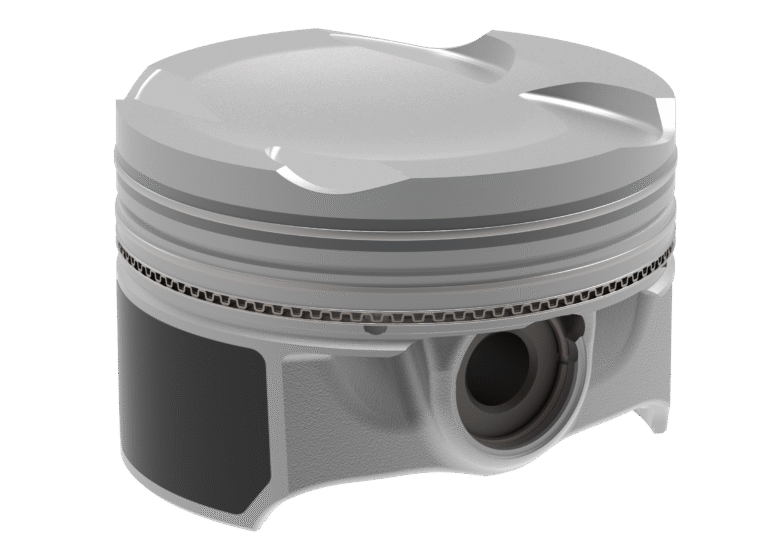

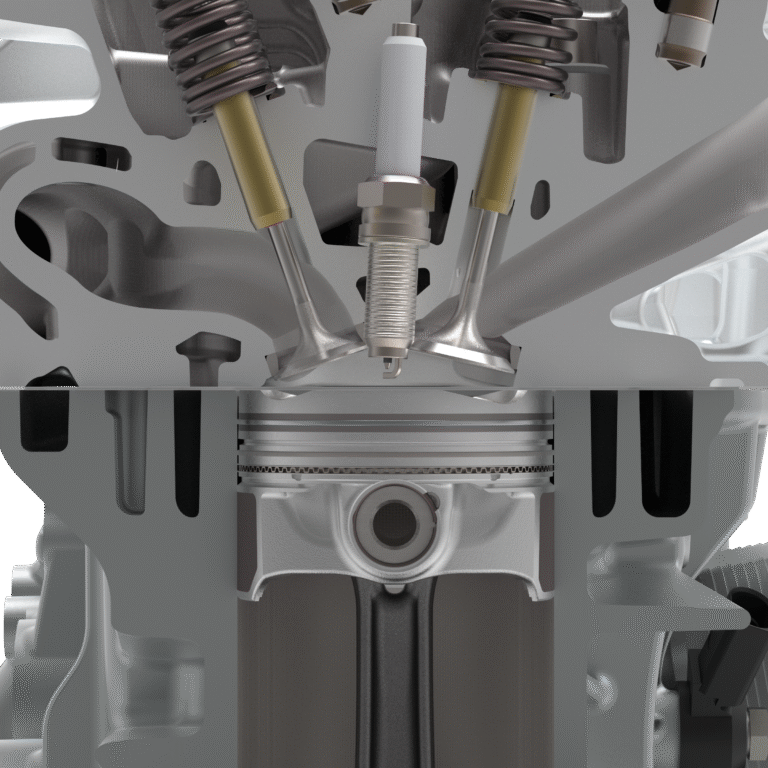

● Another notable feature is the DLC (Diamond-Like Carbon) coating applied to the piston pins, which reduces overall friction losses in the powertrain.

● Reduced friction in the valve train is additionally achieved by using narrower roller elements in the rocker arms of the ACT and ACT+ cylinder deactivation systems, a change originally introduced due to installation constraints.

● For improved heat dissipation, the exhaust valves are hollow and filled with sodium.

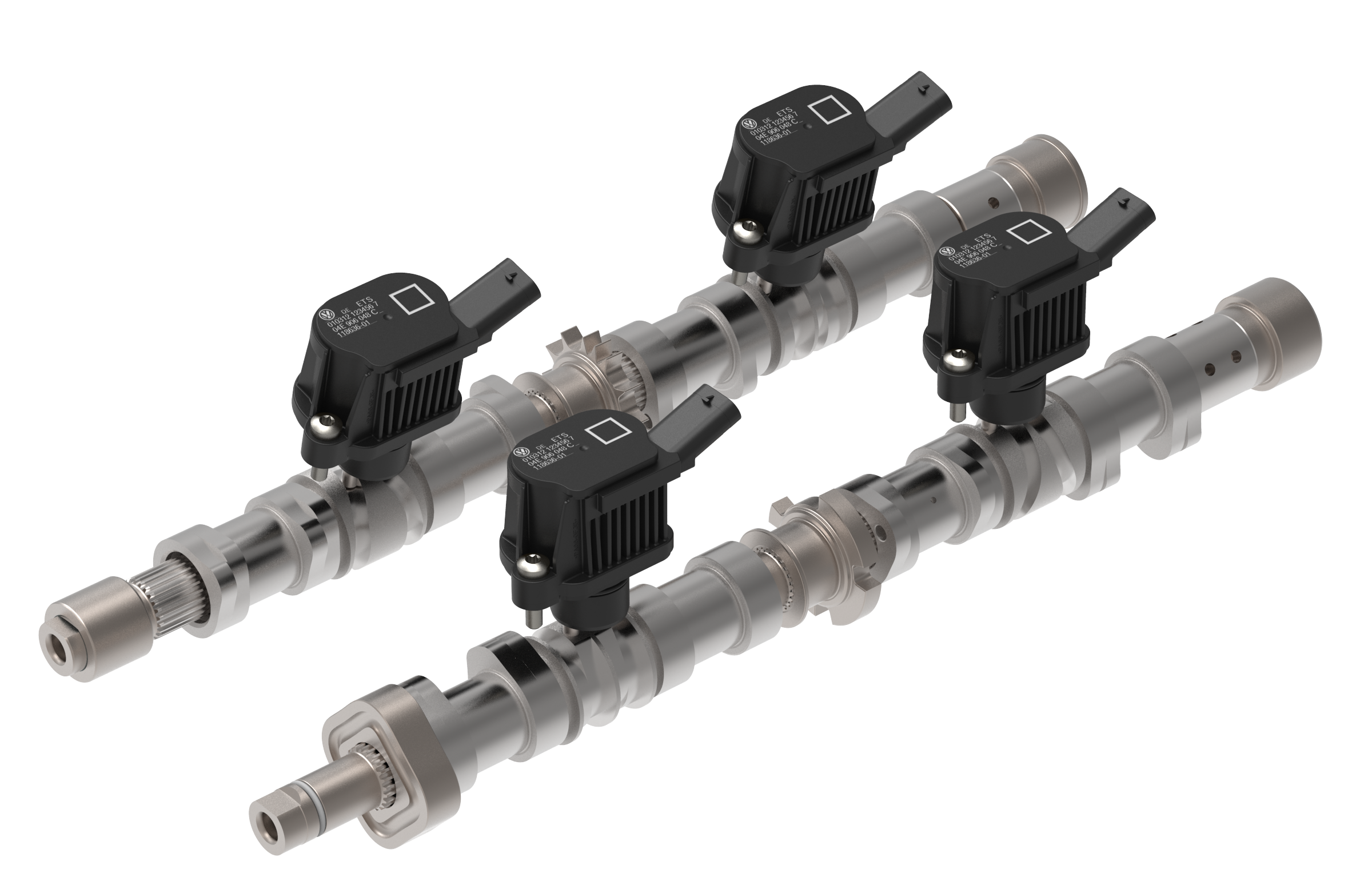

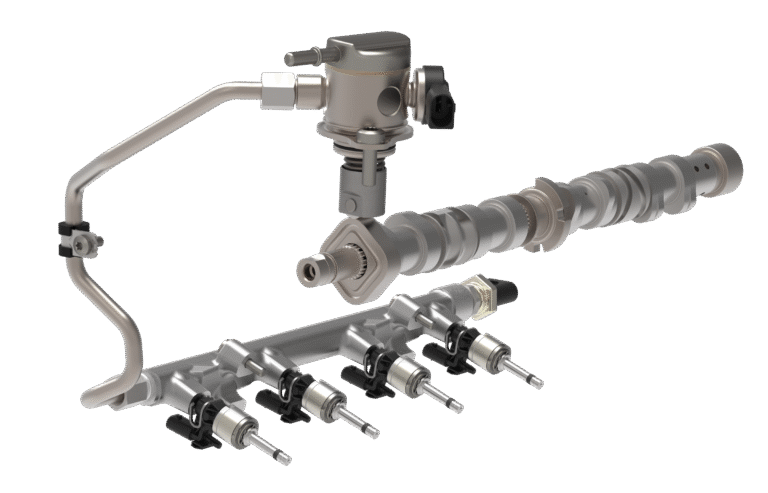

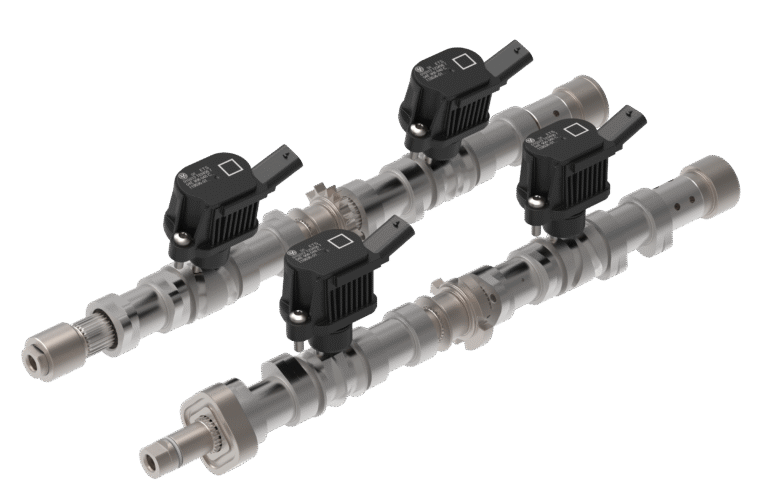

● The camshaft adjusters allow the camshaft to rotate into different positions, providing the flexibility to achieve the lowest fuel consumption for any given load mode. Adjustment is performed using pressurized oil flowing into individual chambers of the adjuster, assisted by the torque on the camshaft generated by the valve springs.