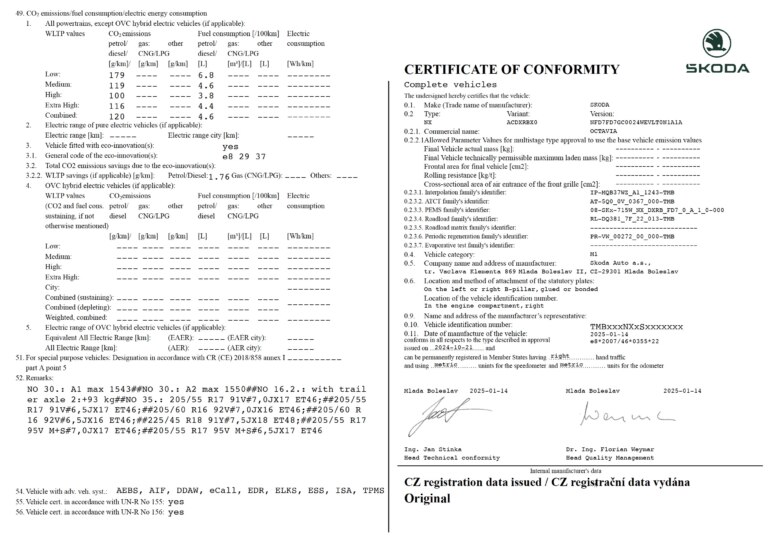

Homologation is a long and demanding journey that culminates in the issuing of a Vehicle Type Approval Certificate. Without it, production lines would remain empty, as this certificate is a mandatory prerequisite for placing a vehicle on the market. It verifies compliance with legislative requirements—primarily those related to safety, emissions, and other vehicle system specifications—have been met.

Legislative requirements vary depending on the markets in which a vehicle is to be sold. As a result, the tests required for Europe differ from those for Australia or for countries in the Persian Gulf, for example.

Testing of impact energy absorption by a headform. No injury may occur upon impact.

Testing of impact energy absorption by a headform. No injury may occur upon impact.

A car as a construction kit

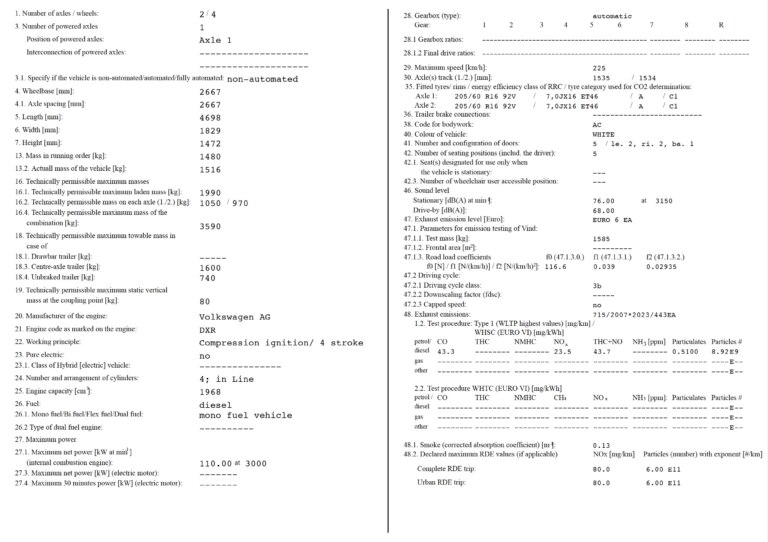

The process begins with individual components. Some of these are homologated directly by the supplier, who is responsible for them, forming the foundation of the entire approval pyramid. “In total, there are around fifty such components, including items such as glass, seat belts, headlights, and tyres,” explains Lukáš Novotný, Vehicle Homologation Coordinator. Škoda Auto requires certificates for all these components in order to proceed to the next steps, known as system approvals.

System approvals are the result of testing the entire vehicle, during which compliance with a further roughly sixty global regulations and EU standards is verified. Their number varies depending on the type of powertrain (petrol/diesel, plug-in hybrid, BEV), the level of driver assistance systems, and the safety features used. The entire homologation process is carried out in cooperation with an independent technical service (such as TÜV SÜD or DEKRA), which is authorised by the approval authority.