Innovation is the driving force of everything that happens at ŠKODA. Countless people in many departments are involved in innovation. The Czech carmaker also has its own Innovation Management team, whose job is to seek out and deliver customer innovations. That means innovations that are truly practical and appealing for customers and that ensure ŠKODA cars move with the times or even set trends.

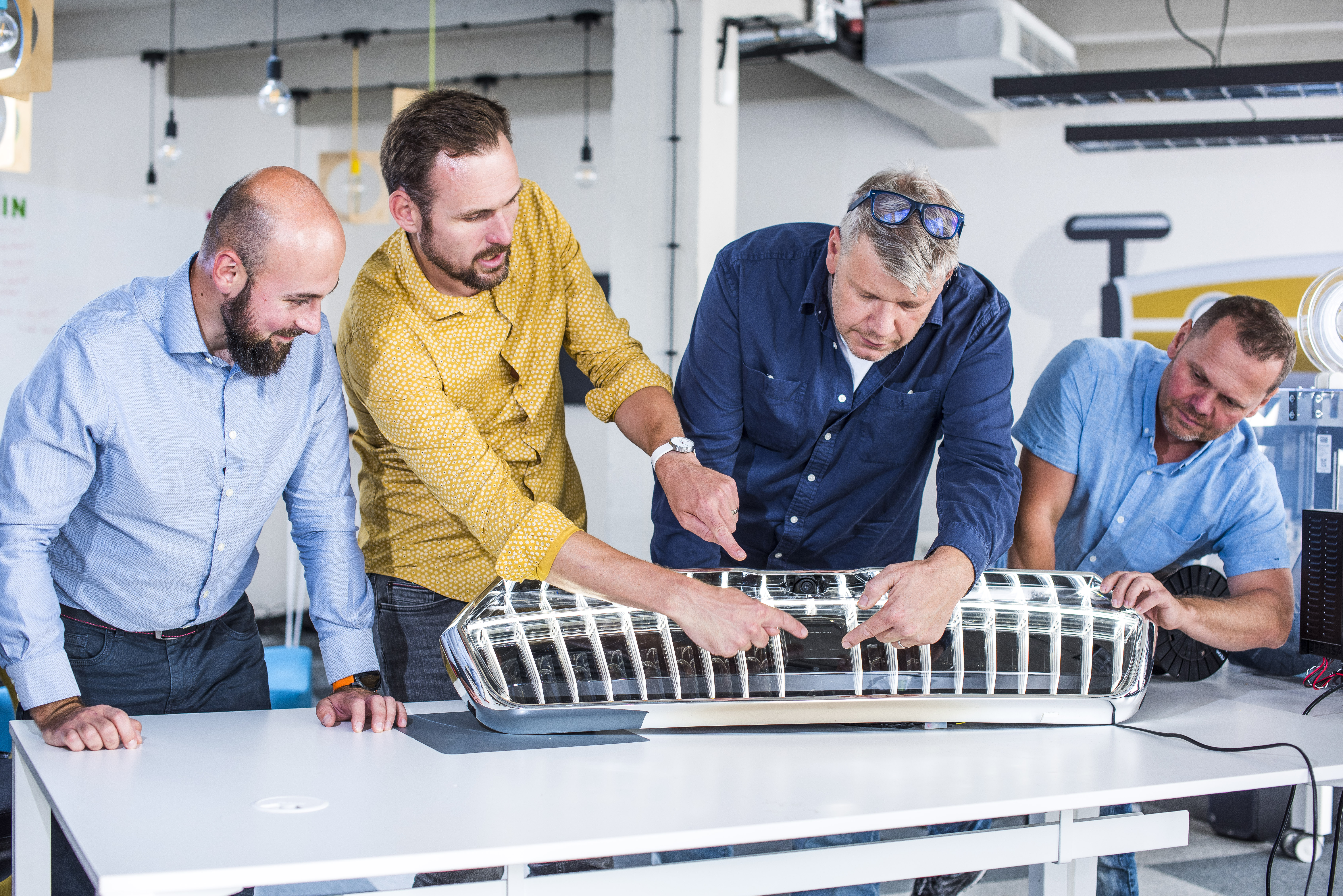

The innovation detail works on various details of both new models and futuristic studies.

The innovation detail works on various details of both new models and futuristic studies.

It is thanks to Innovation Management that innovations like the ice scraper in the fuel tank cap, the tablet holder for rear seat passengers or the funnel for washer fluid integrated into the tank cap saw the light of day. But there are also more complex innovations, such as aerodynamic wheel covers, active air intake adjustment for the radiator or a sound generator for some ŠKODA models.

The innovation team is always trying something new, including various concepts. These include a mobile charging station for electric vehicles that uses a hydrogen fuel cell, an electrified axle or ideas for using recycled materials. Right now they’re working on an idea to make gear changing easier for drivers of manual transmission cars.

One of the innovations – a funnel integrated into the cap of the windscreen washer fluid tank that makes it easier to top up.

One of the innovations – a funnel integrated into the cap of the windscreen washer fluid tank that makes it easier to top up.